What are the maintenance methods for conveyor belt sushi equipment?

Release Time:2024-02-03

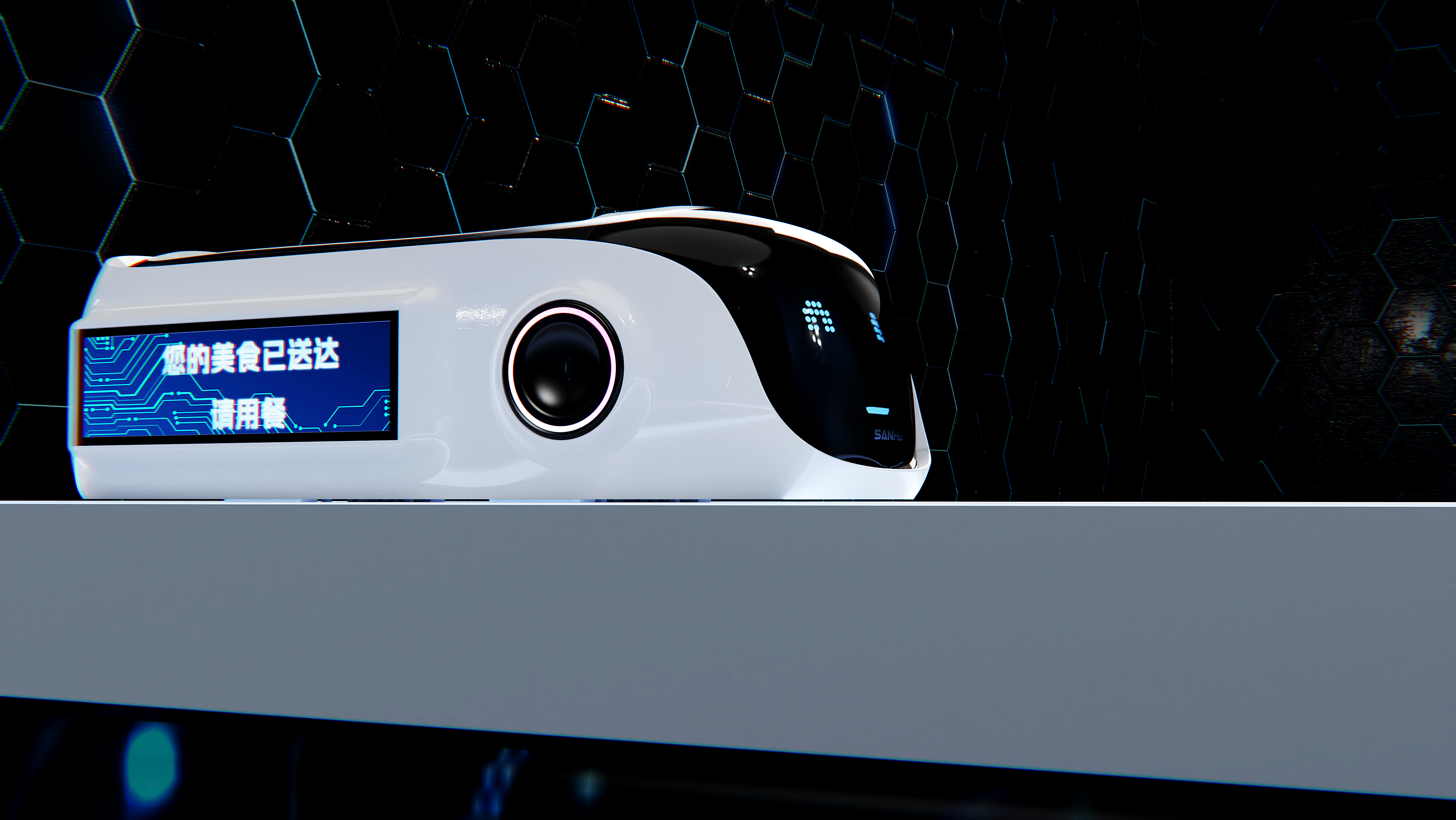

Conveyor belt sushi is a very popular form of catering, and the maintenance of its equipment is very important for operators. Correct maintenance can ensure the normal operation of the equipment, extend its service life, and also provide food safety assurance. The following will introduce the maintenance methods of conveyor belt sushi equipment.

1. Daily maintenance

Clean the control panel: After daily use, wipe the control panel with a damp cloth to remove oil, dust and other impurities to avoid affecting use and touch response. You can use professional cleaners, but be careful not to make it too wet to prevent liquid from entering the inside of the control panel.

Clean the guide rails: The rotation area of the conveyor belt sushi equipment is usually controlled by guide rails. After daily use, the guide rails should be wiped with a cleaning brush or wet cloth to remove food residues and oil stains. Avoid cleaning the rails in reverse to avoid further contamination of the food area.

Clean the conveyor belt: The conveyor belt of the rotary sushi equipment is a food contact area and needs to be kept clean and hygienic. When cleaning the conveyor belt, first turn off the power and wipe it with a damp cloth dipped in special detergent to remove grease and food stains. Then wipe again with clean water to remove any detergent residue.

Clean the food tray: The food tray of conveyor belt sushi equipment is usually made of plastic and should be cleaned in time after daily use to remove residual food and stains. You can use professional cleaners, rinse with water after cleaning, and let dry for later use.

Check the gear transmission: The gear transmission of the rotary sushi equipment is an important power transmission component. The operation of the gear should be checked after daily use to see if there are any abnormal sounds or uneven operation. If there is any abnormality, please contact maintenance personnel for inspection in time.

Cleaning the pool: The pool of the conveyor belt sushi equipment should be used to wet the food area. After daily use, the water in the pool should be drained, and the surface and slot of the pool should be cleaned with a damp cloth or cleaning brush. After cleaning, inject clean water again for flushing to prevent sewage residue from affecting food hygiene.

2. Regular maintenance

Add lubricating oil: Key components of the rotary sushi equipment such as gear transmission require the nourishment and protection of lubricating oil. Check the lubricating oil condition of these components regularly and add or replace them according to the instructions. Be careful not to add too much to avoid excessive lubrication and oil stains.

Clean the motor: Conveyor belt sushi equipment is usually equipped with a motor, and check the operation of the motor regularly. If you find that the motor has abnormal sound, heat, or abnormal operation, you should stop using it immediately and contact professionals for inspection and maintenance. At the same time, regularly clean the cooling fan of the motor with a hair dryer or brush to prevent dust and dirt from causing motor failure.

Clean Sensors: Conveyor belt sushi equipment is often equipped with sensors that sense the arrival and departure of food. Regularly check the operation of the sensor and pay attention to any errors or malfunctions. If you find dust, stains, etc. on the sensor, you can use a hair dryer or brush to clean it to maintain the sensitivity of the sensor.

Check the conductive belt: The conveyor belt of the rotary sushi equipment is usually composed of a conductive belt. Regularly check whether the connection of the conductive belt is tight. If it is loose, it should be repaired in time. At the same time, check the conductive tape for wear, cracks or dirt, and replace or clean it if necessary.

Check the power cord: The power cord of the conveyor belt sushi equipment is an important part of the power supply. Check the power cord regularly to see if it is broken, damaged or short-circuited. If necessary, replace or repair it in time. At the same time, regularly check whether the plug and socket are normal to prevent abnormal current caused by poor contact.

3. Regular inspection and maintenance

Clean the plate holder: The plate holder of the conveyor belt sushi equipment is usually made of metal. Regularly check whether the connection of the plate holder is tight. If it is loose, it should be repaired in time. At the same time, the food plate holders should be cleaned and disinfected regularly to prevent bacterial growth and food contamination.

Check the transmission rack: The transmission rack of the rotary sushi equipment is a key component connecting the motor and the guide rail. Check the connection of the transmission rack regularly. If it is loose, broken or worn, it should be replaced or repaired in time.

Check electrical components: Electrical components of conveyor belt sushi equipment such as relays, contactors, etc. also need to be checked regularly to ensure their normal operation and safe use. If electrical components are found to be hot, falling off, or aging, they should be replaced or repaired immediately to avoid dangers such as short circuits or fires.

Check the water pump and water pipes: Conveyor belt sushi equipment is usually equipped with water pumps and water pipes to supply the water source required for cleaning and rinsing. Regularly check the connections and leaks of water pumps and water pipes. If problems are found, they should be repaired or replaced in time to ensure the normal supply of water.

The above are the maintenance methods of conveyor belt sushi equipment. Operators should follow the above steps in daily use to ensure the normal use of the equipment and extend its service life. At the same time, in order to ensure food safety and hygiene, attention should also be paid to regular cleaning and disinfection of food areas, and regular comprehensive inspection and maintenance of equipment.

CATEGORY

Related News

2024-02-03

Related