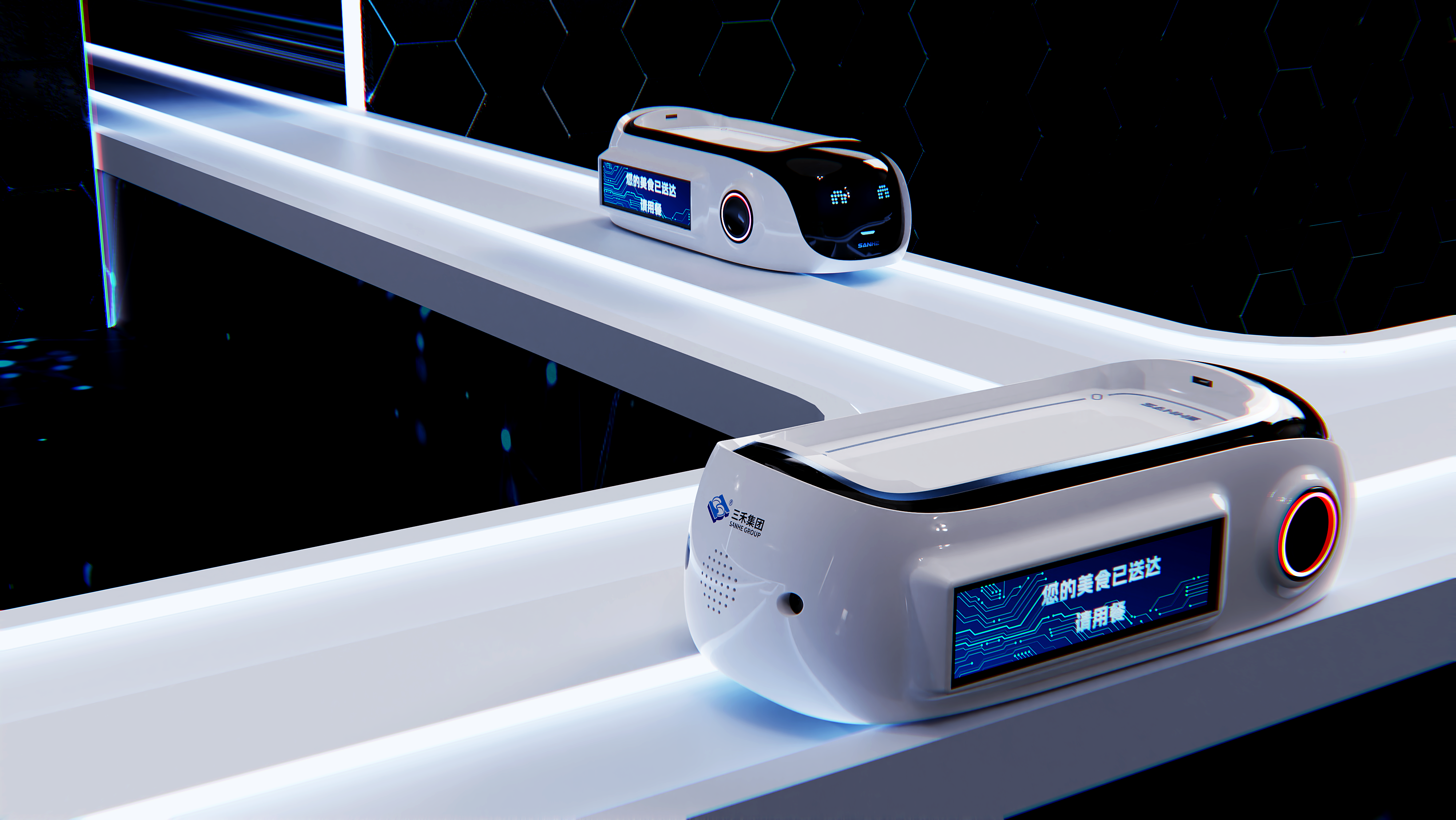

Why Your Business Needs an Intelligent Conveyor System for Food Transport

Release Time:2025-08-20

Why Your Business Needs an Intelligent Conveyor System for Food Transport

Introduction to Intelligent Conveyor Systems

In today’s fast-paced food industry, optimizing transportation and logistics is more critical than ever. **Intelligent conveyor systems** have emerged as a game-changer, providing businesses with the automation and efficiency needed to keep up with demand. These advanced systems not only improve overall productivity but also ensure the safe and hygienic transport of food products throughout the supply chain.

The Importance of Efficient Food Transport

Efficient food transport is vital for several reasons:

1. Maintaining Food Safety Standards

Food safety regulations are strict and vital to consumer trust. Intelligent conveyor systems help meet these standards through:

- Automated tracking systems that monitor temperature and humidity.

- Reduced human handling, which minimizes contamination risks.

- Easy-to-clean designs that comply with food safety regulations.

2. Enhancing Operational Efficiency

An intelligent conveyor system can optimize workflows, allowing businesses to:

- Reduce labor costs by automating repetitive tasks.

- Decrease transport time, increasing throughput.

- Minimize downtime through predictive maintenance features.

Key Features of Intelligent Conveyor Systems

When considering an intelligent conveyor system, it’s crucial to understand the features that set these systems apart:

1. Smart Automation

Through the use of **IoT technology**, these systems can automatically adjust speeds, routes, and loads based on real-time data, ensuring optimal performance.

2. Data Analytics and Reporting

Intelligent conveyor systems collect data on every aspect of the transport process, enabling businesses to analyze performance and identify areas for improvement. Key benefits include:

- Enhanced decision-making based on accurate data.

- Identification of bottlenecks that hinder efficiency.

3. Flexible and Scalable Design

These systems can adapt to various food products and production sizes, making them suitable for businesses of all scales. Features include:

- Modular designs that allow for easy expansion.

- Compatibility with different types of food processing equipment.

Benefits of Implementing Intelligent Conveyor Systems

The advantages of adopting intelligent conveyor systems extend beyond automation. Businesses can expect to see:

1. Improved Product Quality

With precise control over transport conditions, businesses can ensure that food products maintain their quality from processing to packaging. This is achieved through:

- Consistent handling that reduces damage to products.

- Effective temperature control during transport.

2. Increased Safety for Employees

Automating transport reduces the need for manual labor, thereby decreasing the risk of workplace injuries. Benefits include:

- Lower stress levels among employees due to reduced physical demands.

- Enhanced safety protocols that minimize accidents.

3. Cost Reduction

While the initial investment in intelligent conveyor systems can be significant, the long-term cost savings are substantial. This includes:

- Lower operational costs due to reduced labor and maintenance expenses.

- Increased profitability through improved efficiency and reduced waste.

How to Choose the Right Intelligent Conveyor System

Selecting the appropriate conveyor system for your food transport needs requires careful consideration:

1. Assess Your Business Needs

Evaluate the specific requirements of your operation, such as:

- The types of food products being transported.

- The volume and frequency of transport needs.

2. Consider Integration with Existing Systems

Ensure that the new conveyor system can seamlessly integrate with your current equipment and processes to maximize efficiency.

3. Request Demonstrations and Trials

Before committing, ask for demonstrations or trial periods to assess the system’s effectiveness in your specific environment.

Real-World Applications of Intelligent Conveyor Systems in Food Transport

Many businesses have successfully integrated intelligent conveyor systems into their transport processes. Here are a few examples:

1. Food Processing Plants

In food processing plants, intelligent conveyor systems streamline the movement of raw ingredients to production lines, ensuring that the production flow remains uninterrupted.

2. Warehousing and Distribution

These systems are used in warehouses to efficiently manage inventories, facilitating quick sorting and movement of products to distribution points.

3. Retail and Grocery Stores

Retailers utilize intelligent conveyor systems to transport products from storage areas to display shelves, improving stock management and reducing labor needs.

Common Misconceptions About Intelligent Conveyor Systems

Despite the clear benefits, some misconceptions persist regarding intelligent conveyor systems:

1. “They Are Only for Large Businesses”

Many small to medium businesses can benefit from scaled-down versions of these systems designed to fit their operational needs.

2. “They Are Too Expensive”

While the initial investment may be high, the long-term cost savings and efficiency gains often outweigh the upfront costs.

Future Trends in Intelligent Conveyor Systems

As technology advances, intelligent conveyor systems are expected to evolve further, leading to:

- Enhanced integration with artificial intelligence for better predictive analytics.

- Increased use of robotics and autonomous vehicles in food transport.

Frequently Asked Questions (FAQs)

1. What is an intelligent conveyor system?

An intelligent conveyor system is a fully automated solution designed to transport products efficiently and safely within various industrial applications, particularly in the food industry.

2. How does an intelligent conveyor system improve food safety?

These systems reduce human handling and monitor transport conditions, thereby minimizing contamination and ensuring compliance with food safety regulations.

3. Can intelligent conveyor systems work with existing equipment?

Most intelligent conveyor systems are designed to integrate seamlessly with existing machinery, enhancing the overall workflow and efficiency.

4. Are intelligent conveyor systems customizable?

Yes, many systems can be tailored to meet specific business needs, including product types, production sizes, and operational requirements.

5. What are the maintenance requirements for intelligent conveyor systems?

Regular maintenance is essential; however, many systems have predictive maintenance capabilities that help identify potential issues before they become problematic.

Conclusion

In an evolving food industry landscape, **intelligent conveyor systems** are not just an asset; they are essential for businesses aiming to enhance efficiency, safety, and product quality. By investing in these advanced transport solutions, companies can position themselves for success, ensuring they have the tools necessary to meet growing consumer demands and stringent safety standards. Embracing intelligent conveyor systems today will pave the way for a streamlined, efficient, and profitable future in food transport.

Keywords:Intelligent Conveyor System

CATEGORY

Related News

2024-02-03

Related