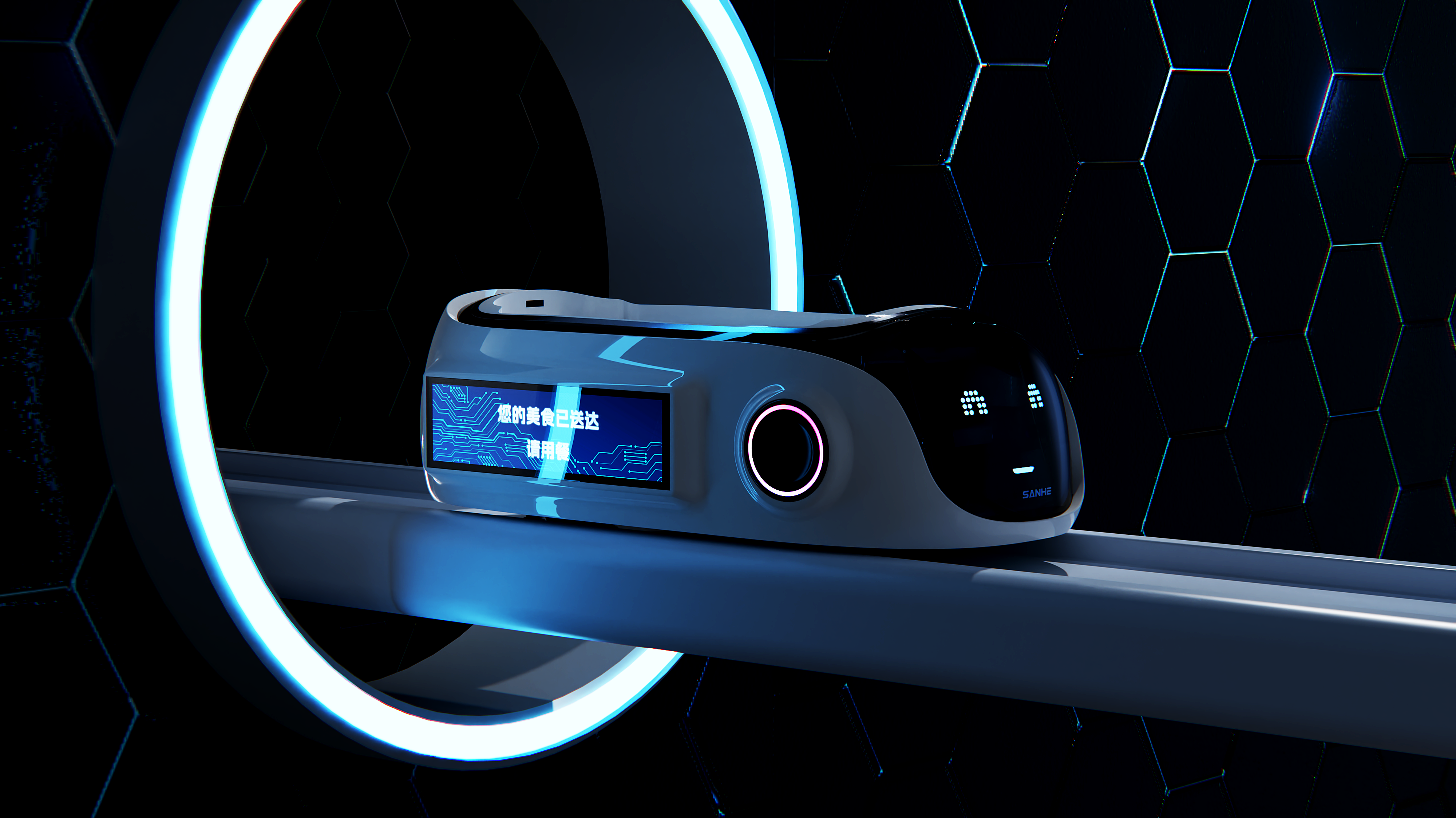

Revolutionizing Food Transportation with Intelligent Conveyor Systems

Release Time:2025-06-18

Intelligent Conveyor Systems are at the forefront of modern food transportation, significantly enhancing the efficiency and effectiveness of logistics within the food industry. These advanced systems are designed to handle the unique challenges associated with food storage and transport, ensuring that products maintain their quality from production to delivery.

One of the key features of Intelligent Conveyor Systems is their ability to automate processes. This automation reduces the need for manual labor, thereby minimizing human error and increasing overall productivity. With the integration of sensors and software, these systems can monitor the flow of goods in real-time, allowing for immediate adjustments as needed. For instance, if a bottleneck occurs at any point in the system, the technology can reroute products to maintain a steady pace, ensuring that food items are delivered promptly.

Moreover, the adaptability of Intelligent Conveyor Systems is another significant advantage. They can be customized to fit various layouts and workflows, accommodating different types of food products, whether they are perishable goods requiring temperature control or packaged items that need careful handling. This flexibility is crucial in an industry where product variety and seasonal fluctuations can impact demand.

In terms of safety, Intelligent Conveyor Systems incorporate various safety features to protect both the food products and the workers involved. For example, advanced detection systems can identify potential hazards, such as jams or foreign objects, preventing accidents and maintaining a safe working environment. Additionally, these systems are often designed to comply with food safety regulations, ensuring that hygiene standards are upheld during the transportation process.

Sustainability is another aspect where Intelligent Conveyor Systems shine. By optimizing the flow of goods, these systems can reduce energy consumption and waste. Many modern conveyors are designed with energy-efficient motors and materials that minimize their environmental impact. As companies increasingly focus on sustainable practices, integrating such intelligent systems can contribute to a more eco-friendly supply chain.

Furthermore, the data analytics capabilities of Intelligent Conveyor Systems provide businesses with valuable insights into their operations. By analyzing the data collected from the system, companies can identify trends, forecast demand, and make informed decisions about inventory management. This data-driven approach can lead to improved efficiency and cost savings in the long run.

In conclusion, Intelligent Conveyor Systems play a pivotal role in enhancing the efficiency and safety of food transportation in the industrial sector. Their automation, adaptability, safety features, sustainability benefits, and data analytics capabilities make them an indispensable asset for businesses looking to improve their logistics and meet the demands of the modern food industry. Embracing this technology not only streamlines operations but also positions companies for future growth in a competitive marketplace.

One of the key features of Intelligent Conveyor Systems is their ability to automate processes. This automation reduces the need for manual labor, thereby minimizing human error and increasing overall productivity. With the integration of sensors and software, these systems can monitor the flow of goods in real-time, allowing for immediate adjustments as needed. For instance, if a bottleneck occurs at any point in the system, the technology can reroute products to maintain a steady pace, ensuring that food items are delivered promptly.

Moreover, the adaptability of Intelligent Conveyor Systems is another significant advantage. They can be customized to fit various layouts and workflows, accommodating different types of food products, whether they are perishable goods requiring temperature control or packaged items that need careful handling. This flexibility is crucial in an industry where product variety and seasonal fluctuations can impact demand.

In terms of safety, Intelligent Conveyor Systems incorporate various safety features to protect both the food products and the workers involved. For example, advanced detection systems can identify potential hazards, such as jams or foreign objects, preventing accidents and maintaining a safe working environment. Additionally, these systems are often designed to comply with food safety regulations, ensuring that hygiene standards are upheld during the transportation process.

Sustainability is another aspect where Intelligent Conveyor Systems shine. By optimizing the flow of goods, these systems can reduce energy consumption and waste. Many modern conveyors are designed with energy-efficient motors and materials that minimize their environmental impact. As companies increasingly focus on sustainable practices, integrating such intelligent systems can contribute to a more eco-friendly supply chain.

Furthermore, the data analytics capabilities of Intelligent Conveyor Systems provide businesses with valuable insights into their operations. By analyzing the data collected from the system, companies can identify trends, forecast demand, and make informed decisions about inventory management. This data-driven approach can lead to improved efficiency and cost savings in the long run.

In conclusion, Intelligent Conveyor Systems play a pivotal role in enhancing the efficiency and safety of food transportation in the industrial sector. Their automation, adaptability, safety features, sustainability benefits, and data analytics capabilities make them an indispensable asset for businesses looking to improve their logistics and meet the demands of the modern food industry. Embracing this technology not only streamlines operations but also positions companies for future growth in a competitive marketplace.

Keywords:Intelligent Conveyor System

Previous

Previous

CATEGORY

Related News

2024-02-03

Related