Streamlining Operations: Intelligent Conveyor Systems in the Food Industry

Release Time:2025-11-12

Streamlining Operations: Intelligent Conveyor Systems in the Food Industry

Table of Contents

- Introduction to Intelligent Conveyor Systems

- Importance of Conveyor Systems in the Food Industry

- How Intelligent Conveyor Systems Work

- Advantages of Using Intelligent Conveyor Systems

- Key Technologies Behind Intelligent Conveyor Systems

- Case Studies: Successful Implementations

- The Future of Conveyor Systems in the Food Industry

- Frequently Asked Questions

- Conclusion

Introduction to Intelligent Conveyor Systems

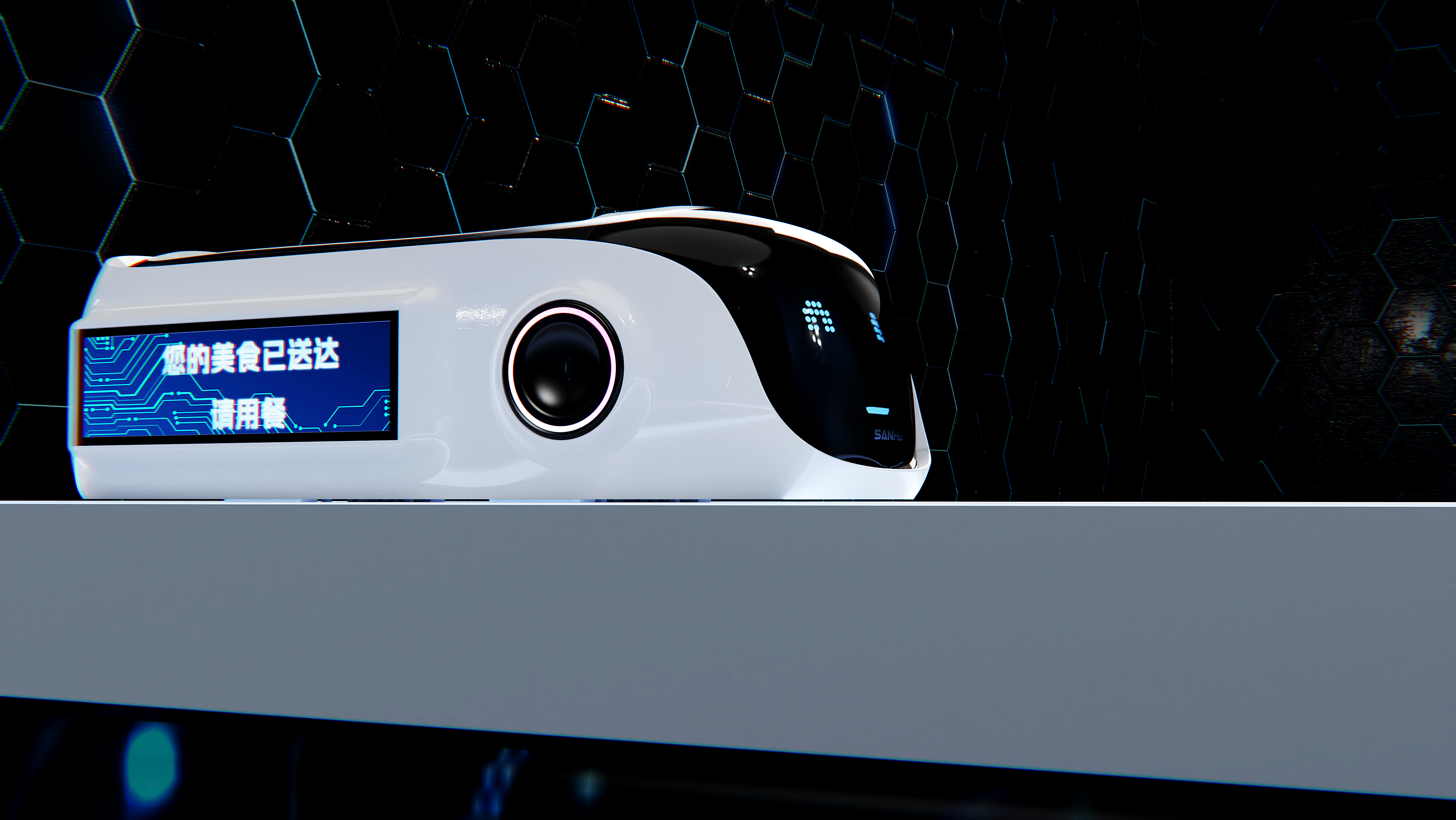

In the rapidly evolving landscape of the food industry, **intelligent conveyor systems** play a crucial role in streamlining operations. These advanced systems automate the transportation of goods, connecting various stages of food processing, packaging, and distribution. By integrating cutting-edge technology, businesses can enhance their overall productivity while adhering to strict safety regulations.

In this article, we will explore the importance of intelligent conveyor systems, their operational mechanics, benefits, and future trends in the food processing sector.

Importance of Conveyor Systems in the Food Industry

The food industry faces unique challenges, including strict hygiene standards and the need for efficient logistics. Intelligent conveyor systems address these challenges effectively. They facilitate the seamless movement of products from one point to another while maintaining product integrity and safety.

These systems are particularly vital in environments where time-sensitive processes are essential, such as in the production of perishable goods. By optimizing workflows, they contribute significantly to operational efficiency and product quality.

How Intelligent Conveyor Systems Work

Intelligent conveyor systems utilize a combination of hardware and software to operate efficiently. The typical components of these systems include:

- **Conveyor Belts**: The backbone of any conveyor system, they transport products along a predetermined path.

- **Sensors**: Equipped with various types of sensors, these systems can monitor the flow of products, detect anomalies, and provide real-time feedback.

- **Controls and Software**: Advanced software allows for the integration of data analytics, enabling operators to make informed decisions based on real-time data.

When combined, these elements create a cohesive system that not only facilitates the physical movement of goods but also optimizes operational workflows.

Advantages of Using Intelligent Conveyor Systems

Implementing intelligent conveyor systems in the food industry offers numerous advantages. Below, we delve into the key benefits these systems provide.

Increasing Operational Efficiency

One of the foremost advantages of intelligent conveyor systems is the **increased operational efficiency**. By automating the transportation of products, these systems reduce the need for manual labor, thereby minimizing human error and enhancing productivity.

Additionally, the integration of smart technology allows for real-time monitoring and adjustments, ensuring that operations run smoothly without unnecessary delays.

Enhancing Food Safety Standards

Food safety is a paramount concern in the food industry. Intelligent conveyor systems enhance food safety through:

- **Reduced Human Interaction**: By minimizing manual handling, these systems lower the risk of contamination.

- **Cleanability**: Designed for easy cleaning, intelligent conveyor systems help maintain hygiene standards.

- **Traceability**: Advanced tracking capabilities ensure that products can be traced throughout the supply chain, making it easier to identify and address issues swiftly.

Reducing Operational Costs

Investing in intelligent conveyor systems can lead to significant **cost reductions** in the long term. By optimizing processes, businesses can lower labor costs and reduce waste. Moreover, the predictive maintenance capabilities of these systems can prevent costly breakdowns and downtime, further contributing to cost savings.

Key Technologies Behind Intelligent Conveyor Systems

The effectiveness of intelligent conveyor systems is underpinned by various technologies. Understanding these technologies is crucial for businesses looking to enhance their operations.

Automation and Robotics

Automation is at the heart of intelligent conveyor systems. With the incorporation of robotic arms and automated guided vehicles (AGVs), these systems can manage complex tasks with precision and speed.

Robotic solutions can handle repetitive tasks such as sorting, packing, and palletizing, significantly reducing the risk of injury for human workers and increasing overall throughput.

Data Analysis and Real-Time Monitoring

Data analytics plays a vital role in optimizing conveyor operations. By collecting and analyzing data from various points in the conveyor system, businesses can gain insights into operational performance.

Real-time monitoring enables operators to identify bottlenecks, monitor product flow, and make immediate adjustments, ensuring that the system operates at peak efficiency.

Smart Technology Integration

The integration of smart technology, such as the Internet of Things (IoT), enhances the functionality of intelligent conveyor systems. With IoT-enabled devices, operators can monitor equipment health and performance remotely, allowing for proactive maintenance and quick troubleshooting.

Smart technology also facilitates communication between different systems, ensuring seamless workflows across various stages of production and distribution.

Case Studies: Successful Implementations

Here, we present a few case studies that highlight the successful implementation of intelligent conveyor systems in the food industry.

**Case Study 1: Bakery Production Facility**

A leading bakery implemented an intelligent conveyor system to streamline its production process. By automating the transfer of dough between mixing, shaping, and baking stations, the bakery increased its output by 30% while reducing labor costs by 20%. Additionally, the system's monitoring capabilities improved product quality and consistency.

**Case Study 2: Fresh Produce Distribution Center**

In a fresh produce distribution center, intelligent conveyor systems were deployed to manage the sorting and packaging of fruits and vegetables. The system utilized real-time data analytics to optimize the flow of products, reducing waste by 15% and significantly speeding up delivery times.

The Future of Conveyor Systems in the Food Industry

As technology continues to advance, the future of conveyor systems in the food industry looks promising. We anticipate several key trends:

- **Increased Automation**: The trend towards greater automation will likely continue, with more businesses investing in intelligent systems to enhance efficiency and reduce labor costs.

- **Artificial Intelligence**: The integration of AI will facilitate smarter decision-making processes, enabling predictive analytics and improved operational foresight.

- **Sustainability**: As environmental concerns grow, there will be a push towards more sustainable conveyor solutions, including energy-efficient systems and environmentally friendly materials.

Frequently Asked Questions

1. What are intelligent conveyor systems?

Intelligent conveyor systems are automated technologies designed to transport goods efficiently while integrating advanced monitoring and data analytics capabilities.

2. How do intelligent conveyor systems enhance food safety?

These systems reduce human contact, are easy to clean, and provide traceability throughout the production and distribution process, thereby enhancing food safety.

3. What are the main benefits of using intelligent conveyor systems?

The main benefits include increased operational efficiency, enhanced food safety standards, and reduced operational costs.

4. What technologies are involved in intelligent conveyor systems?

Key technologies include automation and robotics, data analysis and real-time monitoring, and smart technology integration.

5. Can you provide examples of successful implementations of intelligent conveyor systems?

Yes, examples include a bakery that increased output by 30% and a distribution center that reduced waste by 15% through the use of intelligent conveyor systems.

Conclusion

Intelligent conveyor systems are transforming the food industry by streamlining operations, enhancing safety, and reducing costs. As technology continues to evolve, these systems will become even more integral to the food processing and distribution process. Businesses that adopt intelligent conveyor systems will not only stay competitive but also lead the way in operational excellence and innovation. By investing in these advanced technologies, the food industry can look forward to a more efficient, safe, and sustainable future.

Keywords:Intelligent Conveyor System

CATEGORY

Related News

2024-02-03

Related