The Technology Behind Intelligent Conveyor Systems: What You Need to Know

Release Time:2025-12-24

The Technology Behind Intelligent Conveyor Systems: What You Need to Know

Table of Contents

- 1. Introduction to Intelligent Conveyor Systems

- 2. Understanding Conveyor Systems: An Overview

- 3. Key Components of Intelligent Conveyor Systems

- 4. Benefits of Adopting Intelligent Conveyor Technology

- 5. Applications in Food Storage and Transport

- 6. Future Trends in Smart Conveyor Systems

- 7. Real-World Case Studies of Intelligent Conveyor Systems

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Intelligent Conveyor Systems

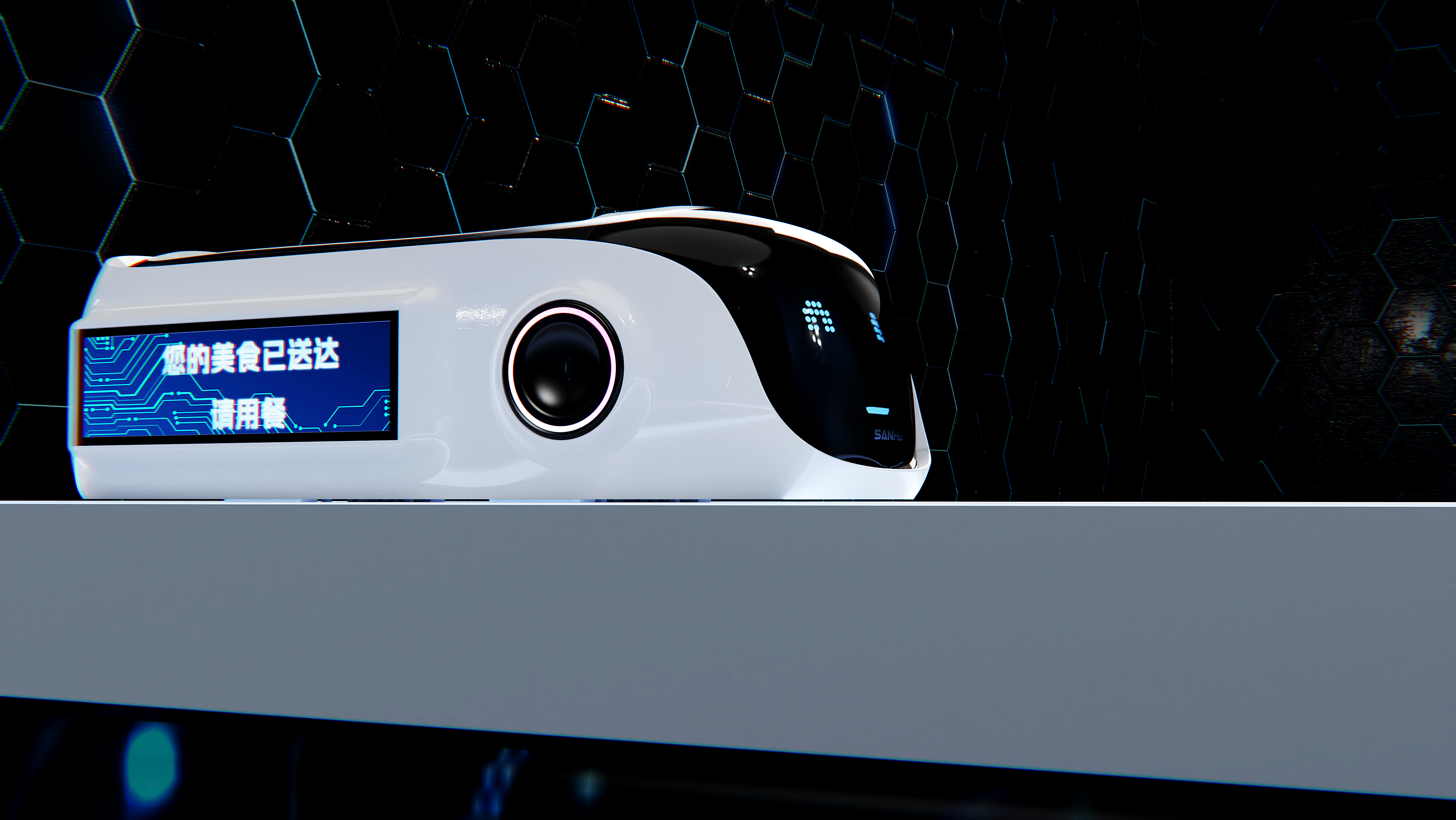

In today's fast-paced industrial environment, the demand for efficient and reliable transportation of goods has never been greater. **Intelligent conveyor systems** represent a significant leap in technology, combining traditional conveyor methods with cutting-edge sensors, software, and automation to optimize material handling processes. This guide will explore what makes these systems "intelligent," their components, benefits, and the future of conveyor technology in the food storage and transportation sector.

2. Understanding Conveyor Systems: An Overview

Conveyor systems are essential in many industries for transporting materials from one point to another. Traditional conveyors operate with a simple mechanical design, typically relying on belts, rollers, and motors to move products along a predetermined path. However, **intelligent conveyor systems** take this basic concept and enhance it with technology that allows for greater flexibility, efficiency, and control.

2.1 The Evolution of Conveyor Systems

Historically, conveyor systems have evolved from basic manual operations to mechanized and, now, intelligent systems. This evolution mirrors advancements in **automation technology**, including robotics and artificial intelligence, which have prompted industries to seek smarter solutions.

2.2 Types of Conveyor Systems

- **Belt Conveyors**: The most common, utilizing an endless belt to transport materials.

- **Roller Conveyors**: Rely on rollers to facilitate movement, ideal for heavy loads.

- **Chain Conveyors**: Suitable for heavy and bulky items, often used in manufacturing.

- **Intelligent Conveyors**: Incorporate sensors and control systems to optimize transport.

3. Key Components of Intelligent Conveyor Systems

To understand the technology behind intelligent conveyor systems, we must examine their critical components:

3.1 Sensors and Monitoring Devices

Sensors play a vital role in the operation of intelligent conveyor systems. These devices monitor various parameters, such as speed, temperature, and product weight. They can detect jams, misalignments, and other issues in real-time, allowing for immediate corrective actions.

3.2 Automation and Control Software

The heart of intelligent conveyor systems lies in their automation capabilities. Control software enables real-time adjustments based on sensor input, facilitating dynamic routing and scheduling of products. This optimizes workflow and minimizes downtime, making operations more efficient.

3.3 Networking and Communication Technologies

Intelligent conveyor systems utilize IoT (Internet of Things) technologies to connect devices and share data. This connectivity allows for centralized monitoring and control, enabling real-time decision-making and enhancing overall system performance.

3.4 Integrated Safety Features

Safety is paramount in industrial operations. Intelligent conveyor systems come equipped with advanced safety features, such as emergency stop buttons, safety barriers, and automatic shut-off mechanisms to prevent accidents and ensure a safe working environment.

4. Benefits of Adopting Intelligent Conveyor Technology

Implementing intelligent conveyor systems offers multiple advantages:

4.1 Increased Efficiency

By automating routine tasks and optimizing routing, intelligent conveyor systems significantly improve **material handling efficiency**. This leads to faster processing times and reduced labor costs.

4.2 Enhanced Flexibility

These smart systems can adapt to changing production demands, allowing for easy reconfiguration of assembly lines and workflows. This flexibility is especially beneficial in industries with fluctuating volumes.

4.3 Improved Safety

With integrated safety features and real-time monitoring, intelligent conveyor systems reduce the risk of accidents and injuries, creating a safer workplace for employees.

4.4 Better Inventory Management

Intelligent systems provide real-time data on inventory levels, enabling businesses to maintain optimal stock levels and reduce excess inventory. This leads to cost savings and improved cash flow.

4.5 Data-Driven Decision Making

The data collected by intelligent conveyor systems can be analyzed to identify trends and inefficiencies, allowing businesses to make informed decisions that enhance overall operational performance.

5. Applications in Food Storage and Transport

Intelligent conveyor systems are particularly advantageous in the food industry, where safety and efficiency are paramount.

5.1 Streamlining Food Processing

Automated conveyor systems facilitate the seamless transport of raw materials, processed goods, and packaging, ensuring that food items move quickly through production lines while maintaining hygiene standards.

5.2 Enhancing Traceability

With integrated sensors and tracking capabilities, intelligent conveyor systems allow for real-time tracking of food products, enhancing traceability and compliance with food safety regulations.

5.3 Reducing Waste

By optimizing transport routes and minimizing delays, these systems help reduce food spoilage and waste, contributing to more sustainable food production practices.

6. Future Trends in Smart Conveyor Systems

As technology continues to evolve, so too will intelligent conveyor systems. Here are some trends to watch:

6.1 Increased Use of AI and Machine Learning

AI and machine learning will play a crucial role in the future of conveyor technology, enabling systems to learn from data and optimize operations autonomously.

6.2 Greater Integration with Robotics

The integration of robotics with intelligent conveyor systems will enhance automation, allowing for seamless cooperation between machines and human workers in production environments.

6.3 Enhanced Sustainability Features

Future systems will likely focus on sustainability, incorporating energy-efficient designs and materials to minimize environmental impact.

6.4 Development of Autonomous Conveyor Systems

The future may see the emergence of fully autonomous conveyor systems capable of operating without human intervention, further enhancing efficiency and reducing labor costs.

7. Real-World Case Studies of Intelligent Conveyor Systems

Examining real-world applications can provide valuable insights into the effectiveness of intelligent conveyor systems:

7.1 Case Study: Food Manufacturing

A leading food processing company implemented an intelligent conveyor system that reduced their processing time by 30%. The integration of real-time monitoring and control software allowed them to identify bottlenecks and streamline operations effectively.

7.2 Case Study: E-commerce Warehousing

An e-commerce giant adopted an intelligent conveyor system in their warehouse, automating the sorting and packing process. The result was a 50% increase in order fulfillment speed, significantly improving customer satisfaction.

8. Frequently Asked Questions

8.1 What is an intelligent conveyor system?

An intelligent conveyor system is an advanced material handling solution that integrates automation, sensors, and software to optimize transportation processes.

8.2 How do intelligent conveyor systems improve efficiency?

By automating material movement, reducing downtime, and optimizing routing, intelligent conveyor systems enhance overall operational efficiency.

8.3 Are intelligent conveyor systems expensive to implement?

While the initial investment can be significant, the long-term savings through increased efficiency and reduced labor costs often justify the expense.

8.4 What industries benefit from intelligent conveyor systems?

Intelligent conveyor systems are beneficial across various industries, including food processing, e-commerce, manufacturing, and pharmaceuticals.

8.5 How do I choose the right intelligent conveyor system for my needs?

Consider factors such as the type of products being transported, required speed, flexibility, and available space when selecting an intelligent conveyor system.

9. Conclusion

Intelligent conveyor systems represent a significant advancement in the field of material handling, particularly in the food storage and transport industry. By integrating cutting-edge technology, businesses can enhance efficiency, safety, and sustainability in their operations. As we look to the future, the ongoing evolution of these systems promises to further revolutionize how industries manage their supply chains. Embracing intelligent conveyor technology is not just an investment in equipment; it is a strategic move toward smarter, more efficient operations.

Keywords:Intelligent Conveyor System

CATEGORY

Related News

2024-02-03

Related